PRODUCT

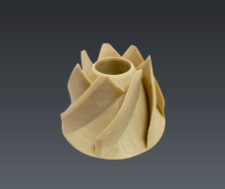

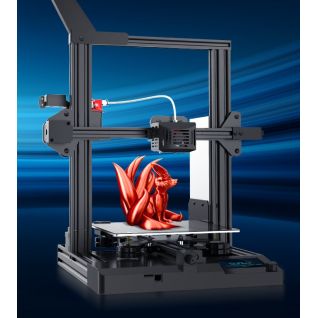

GTF570-Y HT FDM 3D Printer

Typical high temperature FDM 3D printer, mostly industrial applications, with up to 500℃ printing, 200℃ hot bed, 120℃ printing chamber temperature. It compatible with most polymer materials, especially workable with high temperature special industrial materials such as PEEK, PEKK, PPSU, ULTEM, etc. It is equipped with detachable double printing nozzles, water cooling system, ball screw + linear guide rail high-precision transmission, also well-known components for the best performance.

It has the properties of high stability, high accuracy, easy operation, easy maintenance, can be widely used in the applications such as aerospace, automotive, medical, tooling, etc.

|

Building size |

500*500*700 mm |

Nozzle Temp. |

500℃ |

|

Hot bed Temp. |

180℃ |

Chamber Temp. |

150℃ |

|

Consumable box Temp. |

65℃ |

Cooling system |

Independent lifting double liquid cooling system sprinkler |

|

Extrusion system |

Dual nozzle system |

Wire diameter |

1.75mm |

|

Positioning accuracy |

X/Y: 2.5μm, Z: 0.78μm |

Printing speed |

0~150mm/s |

|

Printing platform |

Carbon fiber board or polymer membrane, vacuum absorption |

Platform Temp. |

180℃ |

|

Hot bed material |

Silica gel |

Layer thickness |

0.05~0.3mm |

|

Nozzle diameter |

0.4mm (default), 0.6/0.8/1.0mm |

Data transmission |

SD card / WIFI |

|

Operating environment |

15~30℃, relative humidity 10~90%, no condensations |

Storage Temp. |

-25~55℃, relative humidity 10~90%, no condensations |

|

Slicing software |

Cura, Simplify3D |

Operating system |

Windows 64 bit |

|

Input format |

.stl/.obj/.3dm |

Machine dimensions |

1080(L)*1380(W)*1950(H) mm |

|

Packing dimensions |

1300(L)*1600(W)*2300(H) mm |

Net weight |

750kg |

|

Gross weight |

850kg |

Power |

6500W, 200~250V, 50~60Hz |

|

Materials |

PEEK, CF-PEEK, PEKK, CF-PEKK, PEI 1010/9085, PPSU, PC, CF-PC, PA, CF-PA, GF-PA, ASA, ABS, CF-ABS, PETG, HIPS, TPU, PLA, CF-PLA, PVA, ESD-safe |

||