PRODUCT

SLA, DLP, LCD 3D printer resin

Light curing resin has 2 categories: stereolithography apparatus resin, and UV resin, which one is for SLA machine application and the other one for DLP and LCD 3D printers’ applications. It contains many semi-types which can fulfill different applicatins such as transparency, high tensile strength, high temperature resistance, high accuracy.

Currently, the SLA technology is widely used in the applications of prototyping, molding, tooling & fixture, automotive, etc.; meanwhile, the DLP and LCD type 3D printers are widely used in dental, medical, surgery simulation, shoes, etc.

|

Product type |

Parameters |

Features |

Applications |

|

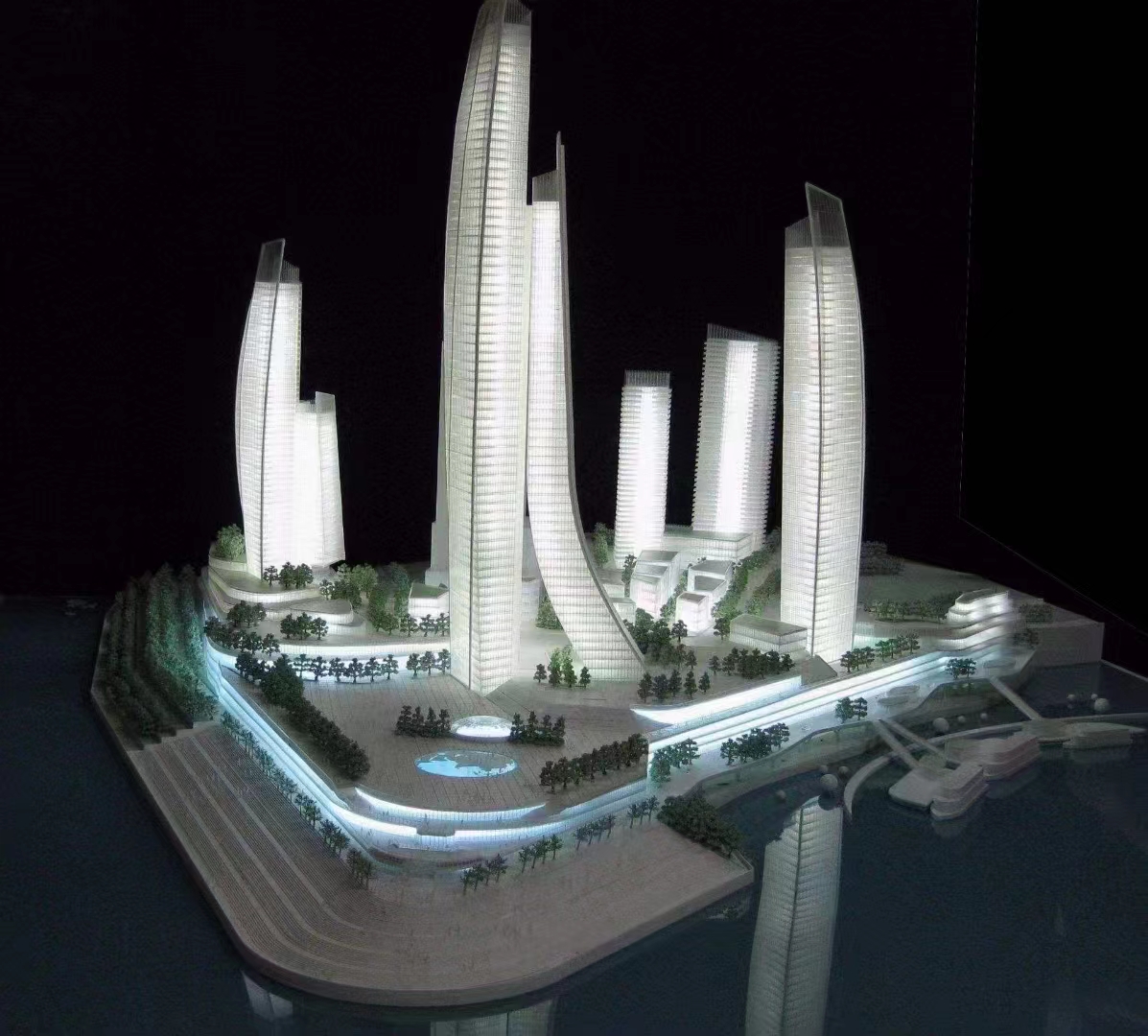

SLA resin |

Tensile strength: 60.37MPa Bending strength: 96.88MPa Max. bending strength: 556.79MPa Elongation: 7.95% Shore hardness: 83D Heat distortion temperature: 57℃ |

|

Widely used for prototyping, medical, automotive, construction |

|

Ragid resin |

Bottom solidification: 40~60s Solidification: 2.5~3.5s Shore hardness: 82~86D Viscosity: 100~150cps Density: 1.1g/cm3 Bending strength: 72~80MPa Tensile strength: 40~50MPa Elongation: 4~9% Wave length: 365~405nm |

|

Compatible with LCD / DLP 3D printers, very good for industrial design, education, art design, etc., both for industrial and consuming purpose |

|

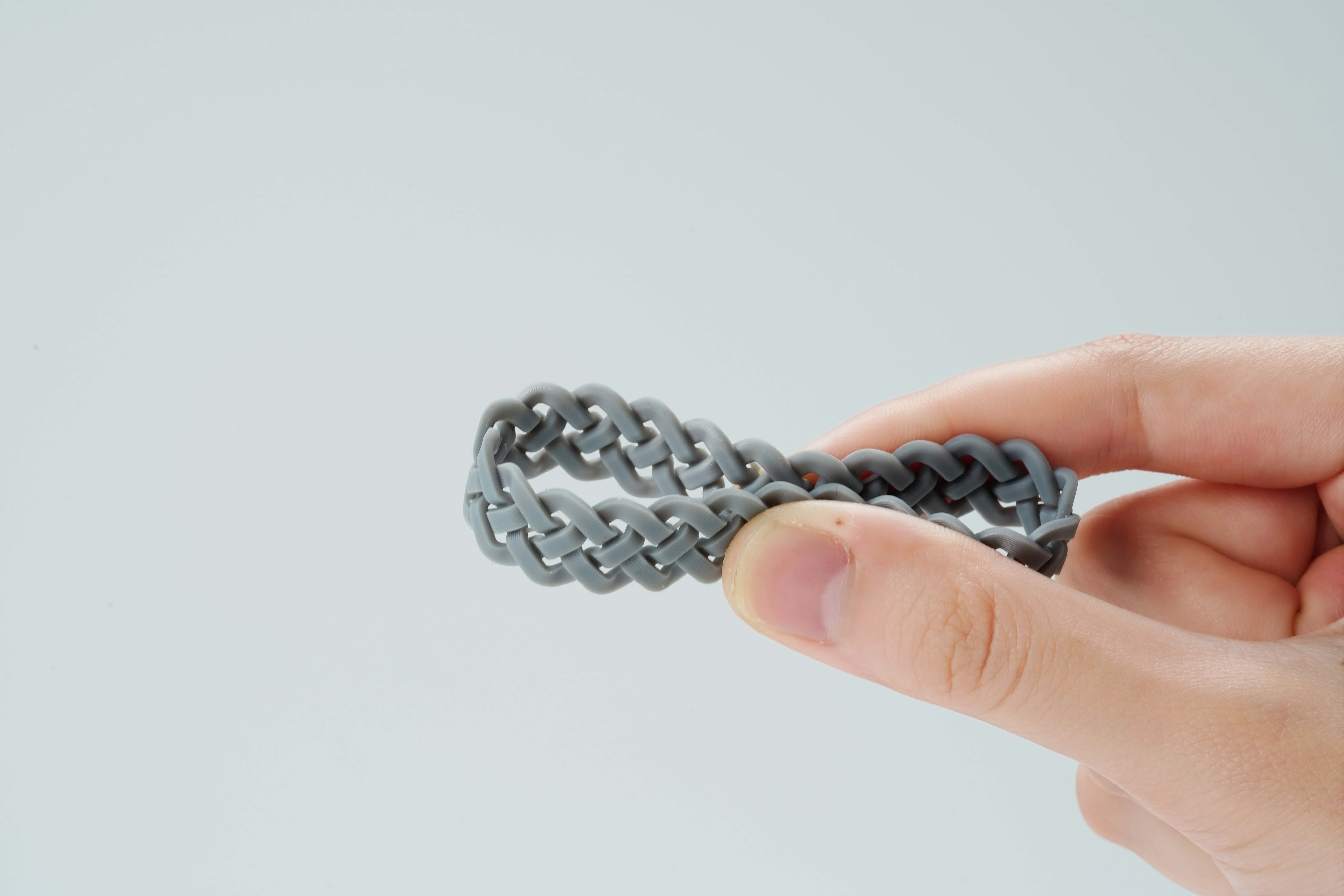

Tough resin |

Bottom solidification: 30~60s Solidification: 2~4s Shore hardness: 78~82D Viscosity: 250~350cps Density: 1.1g/cm3 Bending strength: 72~80MPa Tensile strength: 36~43MPa Elongation: 14~20% Wave length: 365~405nm |

|

Compatible with LCD / DLP 3D printers, wide applications. |

|

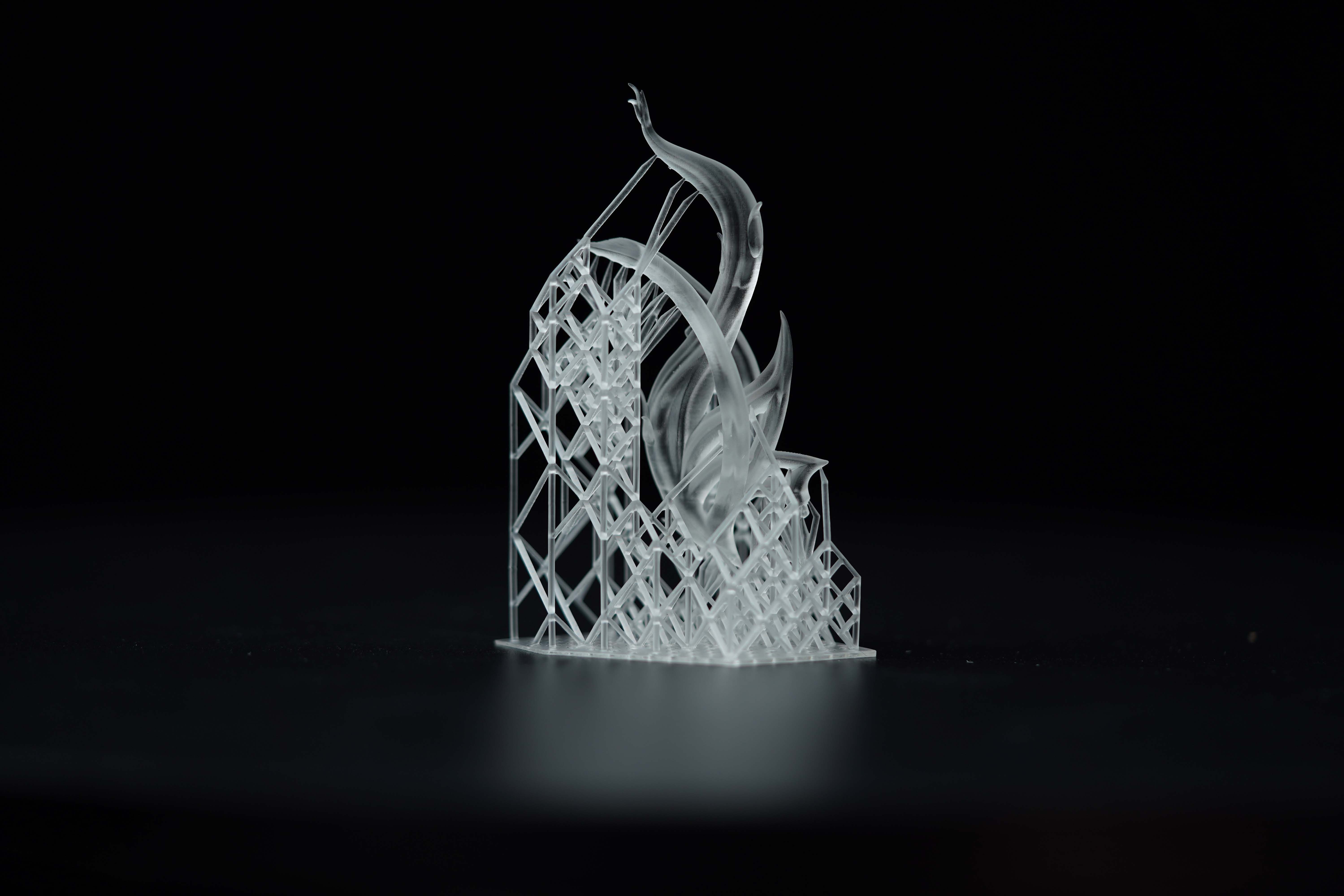

Transparent resin |

Bottom solidification: 20~40s Solidification: 1.5~2.5s Shore hardness: 82~86D Viscosity: 100~150cps Density: 1.1g/cm3 Bending strength: 72~80MPa Tensile strength: 40~50MPa Elongation: 4~9% Wave length: 365~405nm |

|

Compatible with LCD / DLP 3D printers, for special application with components’ transparency requirement |

|

Micro-engraving resin |

Bottom solidification: 40~60s Solidification: 2.5~3.5s Shore hardness: 78~84D Viscosity: 100~150cps Density: 1.1g/cm3 Bending strength: 72~80MPa Tensile strength: 40~50MPa Elongation: 4~9% Wave length: 365~405nm |

|

Compatible with LCD / DLP 3D printers, specifically designed for micro or small model printing with high accuracy and performance |

|

Red wax |

Bottom solidification: 40~60s Solidification: 2.5~3.5s Shore hardness: 78~84D Viscosity: 100~150cps Density: 1.1g/cm3 Bending strength: 72~80MPa Tensile strength: 40~50MPa Elongation: 4~9% Wave length: 365~405nm |

|

Compatible with LCD / DLP 3D printers, for detail expression and sharpness, good for prototyping |

|

Matte resin |

Bottom solidification: 40~60s Solidification: 2.5~3.5s Shore hardness: 85D Viscosity: 350~450cps Density: 1.1g/cm3 Bending strength: 60~70MPa Tensile strength: 40~45MPa Elongation: 2~4% Wave length: 365~405nm |

|

Compatible with LCD / DLP 3D printers, suitable for hand-made printing, model design |