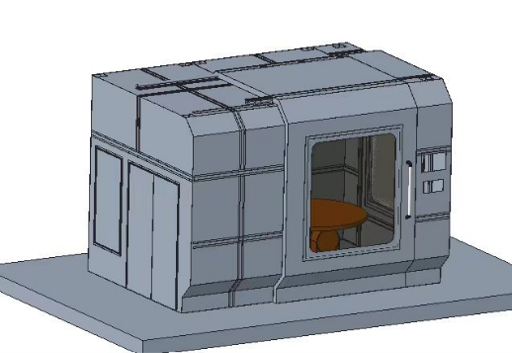

PRODUCT

GT-WAAM1500

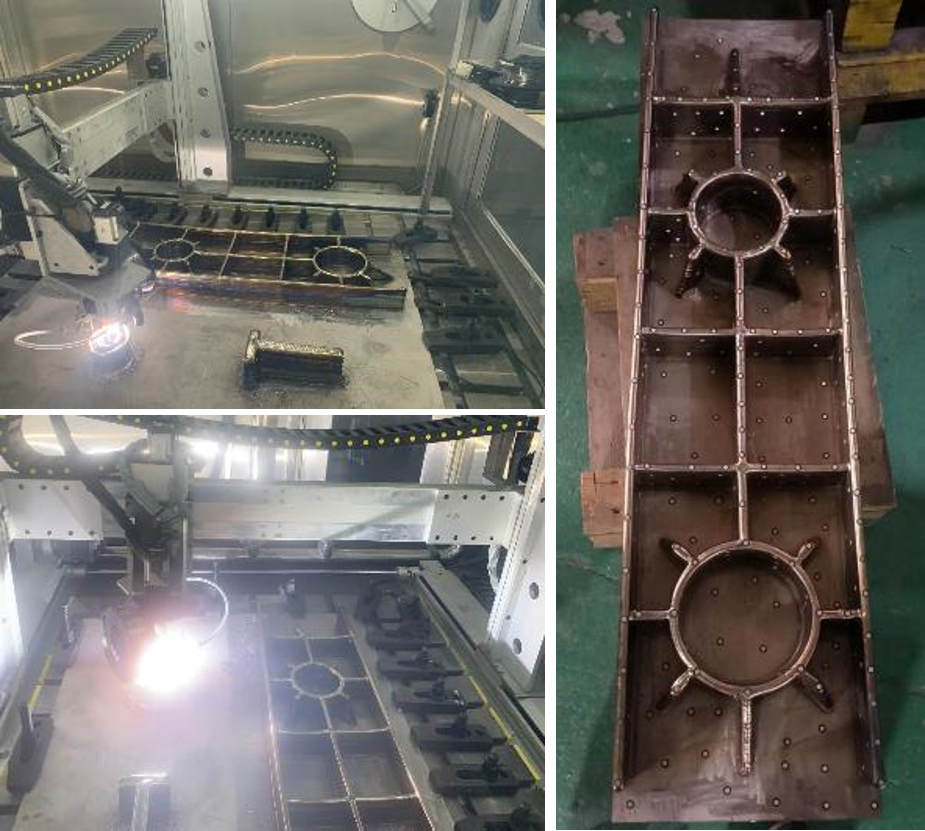

WAAM is one technology using arc as energy and wire as raw material to forming specific geometry according to 3d model and software scanning strategy. It is widely used in verious applications such as aerospace, aviation, energy, defence, metalurgy, etc., which is one of the most cost-competetive technology, especially for big size parts forming/printing.

It has advantages of high efficiency, low cost, easy operation, etc.

Specifications

| Welder | Fornius CMT 4000 ADV. |

| Printing size | 1500*1500*1000mm |

| Printing material | Low carbon steel, stainless steel, superalloy, aluminum alloy |

| Protective enviroment | Argon |

| Current | 3-400A |

| Oxygen content | <100ppm |

| Layer thickness | 0.5-3.5mm |

| Wire feeding speed | 0.3-10 m/min |

| Positioning accuracy | ±0.05mm |

| Printing accuracy | ±0.5mm |

| Printing efficiency | 0.3-8kg/h |

| Printing speed | 0-10mm/s |

| Substrate pre-heat | 0-200℃ |

The machine is customizable.