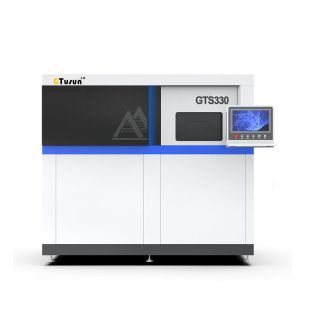

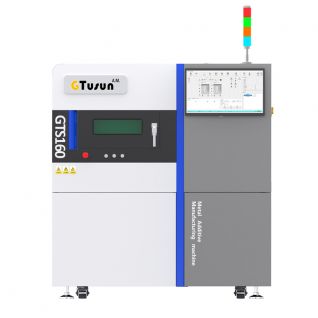

PRODUCT

GTS140-M Dentistry SLM 3D Printer

The GTS140-M is a typical small SLM machine, especially for medical applications such as denture printing, Dental brace printing, implants printing, etc. It applies widely with the materials like titanium alloy, chrome-cobalt alloy, aluminum alloy, etc.

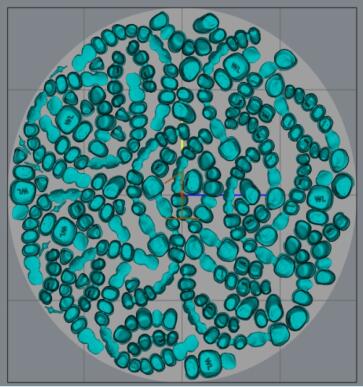

After that, the utilization of the advanced software can help operators fast and accurately place parts to be printed and make the printing efficient.

§ 180~200 teeth in 6 hours printing

§ Quick typesetting, avg. 5 minutes for each print

§ Built-in camera for printing monitoring

§ Integrated welding structure, strong stability, easy installation

§ Intelligent interface, easy operation

§ Reliable and robust, matured processes

|

Building size |

φ140*100 mm |

|

Laser power |

380W (500W optional) |

|

Substrate heat |

250℃ |

|

Scanner |

High speed scanner |

|

Laser spot |

50~80 μm |

|

Max. Scan speed |

7 m/s |

|

Laser thickness |

10~40 μm |

|

Accuracy |

±0.1mm (<100mm), ±0.1% (>100mm) |

|

Power |

5 kW |

|

Materials |

Titanium alloy, Cobalt-chromium alloy, Aluminum alloy, Stainless steel, Die steel, etc. |