PRODUCT

GTS180-M Dentistry SLM 3D Printer

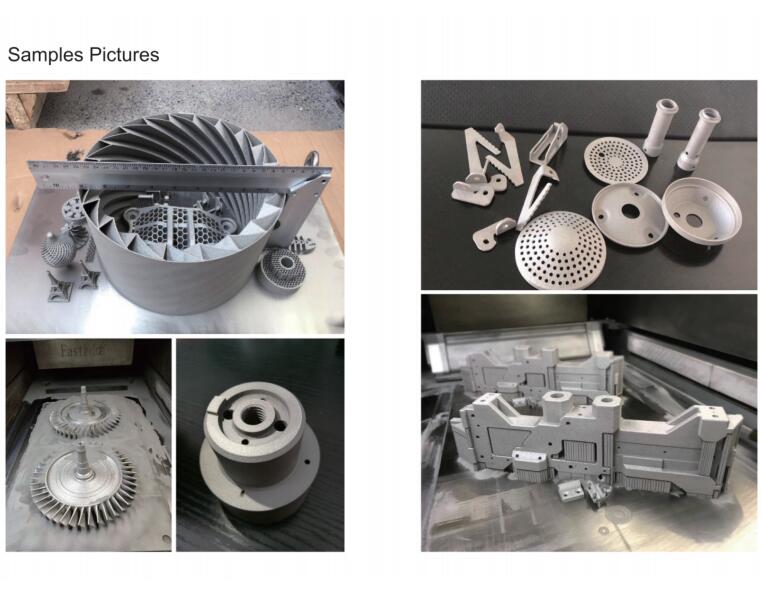

§ 350 teeth in 6 hours printing, 80 braces in 24 hours printing

§ Up powder feeding, use less powder

§ Bidirectional powder recoating

§ Splicing printing is available

§ Quick typesetting, avg. 5 minutes for each print

§ Built-in camera for printing monitoring

§ Integrated welding structure, strong stability, easy installation

§ Intelligent interface, easy operation

§ Reliable and robust, matured processes

Description

GTS140-M is typical 3D printer for teeth, support printing application, it only applies very small area, quite adapt to the sites with limited space. Also, it has ideal layer slicing and path generation. Path generation and full support design can be activated with only 1 click.

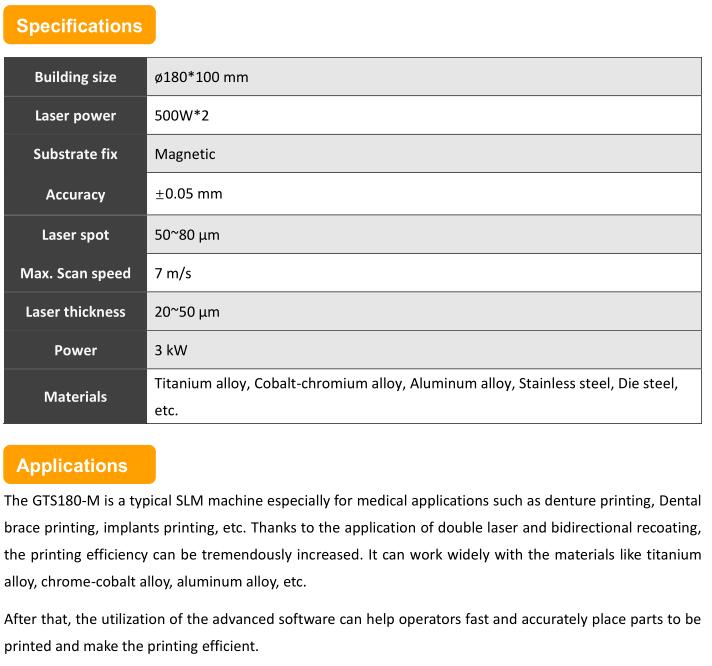

Specifications

|

Building size |

ø180*100 mm |

|

Laser power |

500W*2 |

|

Substrate fix |

Magnetic |

|

Accuracy |

±0.05 mm |

|

Laser spot |

50~80 μm |

|

Max. Scan speed |

7 m/s |

|

Laser thickness |

20~50 μm |

|

Power |

3 kW |

|

Materials |

Titanium alloy, Cobalt-chromium alloy, Aluminum alloy, Stainless steel, Die steel, etc. |