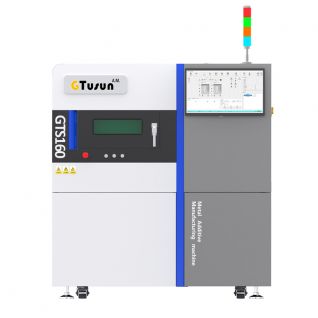

PRODUCT

GTS300-M SLM 3D printing machine

▪ Advanced laser and scanner

▪ Up powder feeding, use less powder

▪ Bidirectional powder recoating

▪ Built-in camera for printing monitoring

▪ Integrated welding structure, strong stability, easy installation

▪ Intelligent interface, easy operation

▪ Reliable and robust, matured processes

The GTS300-M is a generic SLM machine for various applications such as medical like denture and implants

printing, automotive, die or casting mold, etc. Thanks to the application of the bidirectional recoating, the

printing efficiency can be effectively increased. It can work widely with the materials like stainless steel,

titanium alloy, chrome-cobalt alloy, aluminum alloy, etc.

After that, the utilization of the advanced software can help operators fast and accurately place parts to be

printed and make the printing efficient.

|

Building size |

300*300*300 mm |

|

Laser power |

500W / 500W*2 / 1000W / 1000W*2 |

|

Substrate temperature |

0~200℃ |

|

Beam focus diameter |

50~300 μm |

|

Max. Scan speed |

7 m/s |

|

Layer thickness |

20~80 μm |

|

Power |

6 kW |

|

Inert air protection |

0.5~1.5 L/min |

|

Air circulation system |

0~1.5 m3 |

|

Z-axis resolution |

0.001mm |

|

Scanning accuracy |

Scanning repeat positioning accuracy ≤2μrad; Linearity 99.9%, ±20%, proportional drift: 8PPM/°C |

|

Materials |

Titanium alloy, Cobalt-chromium alloy, Aluminum alloy, Stainless steel, Die steel, etc. |